Our first “Pulse Check”. It’s Ryan Duffy, Editor-in-Chief of Per Aspera.

The national conversation around American industry is loud — but rarely clear. So Per Aspera teamed up with the good folks at NAIA (New American Industrial Alliance) to run original research with The Harris Poll, a market research firm. Together, we created and conducted a national survey to get an honest read on how Americans are processing the economic and technological shifts around them.

What we found isn’t a tidy narrative, but a set of tensions: broad support, low familiarity, cautious momentum. A country that wants to build — but isn’t always sure how. This isn’t about prediction. It’s about orientation. Where things are shifting, where they’re stuck, and what that means for anyone trying to move them forward.

This is Per Aspera’s first-ever Pulse Check on the nation.

America’s Industrial Mood, Quantified

We started with a simple question: How do Americans really feel about reindustrialization? And we ended up with the Per Aspera/NAIA x Harris Poll Reindustrialization Survey, featuring a dozen-plus questions, thousands of datapoints, a six-month spread across two waves, and responses from 2,138 American adults.

What we uncovered: A public whose views are crystallizing. Attitudes are hardening around the need to build at home, softening towards the technology that will help do it, and converging into a broad public mandate to reindustrialize (and reskill).

The key takeaways: Nearly nine in ten Americans say “Build here.” Roughly two-thirds strongly agree that domestic production is essential for the economy, with 88% in total agreeing. Support sits above 80% in almost every way we can slice it (age, income, education). At the same time, more than eight in ten Americans agree that the public doesn’t understand high-tech factories, and only 25% feel very confident in their own understanding. Desire and understanding are pulling in opposite directions.

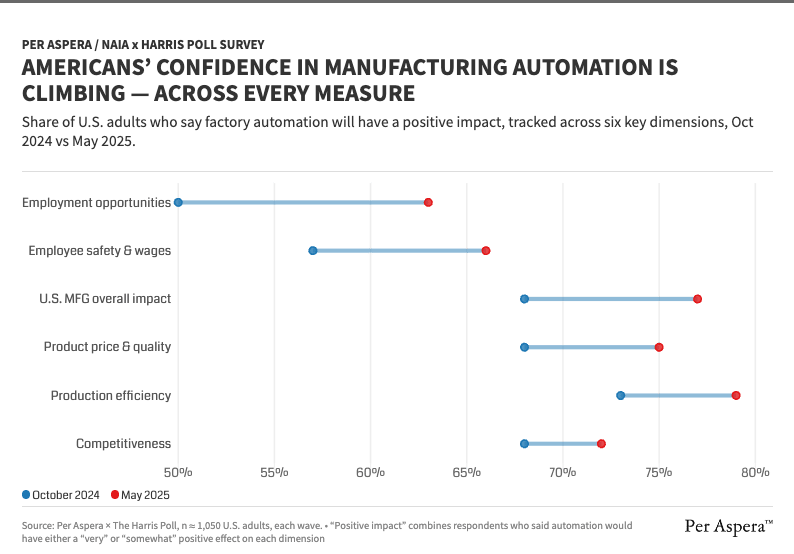

On the automation question…This was the sharpest swing across six months that we clocked. Net-positive views are climbing across every measure:

Still, Gen Z and lower-income adults say Not sure roughly a third of the time when asked whether automation will boost jobs, wages, and U.S. competitiveness — almost 2× as often as Boomers or six-figure earners. This signals a tension.

When it comes to China, Americans are equally clear-eyed and restless. A plurality believes the U.S. trails China in advanced manufacturing today, but expects the U.S. to lead by 2035. The public has a robust, almost defiant, optimism for future American leadership. We call this “resurgent realism,” and see it as a critical psychological asset for reindustrialization efforts.

Where are the gaps? Predictably…education, income, and age drive most splits in attitudes. But the crosstabs also served us some curveballs, from the loudest champions of a vocational revival to the “new industrial optimists” most bullish on a U.S. industrial comeback. The full writeup unpacks these dynamics more…

Where do we go from here? Five tensions define the road ahead:

Made-in-America mandate: Near-unanimous support for domestic production affords leaders rare political oxygen for bold moves, but credibility rides on visible, local wins.

Uneasy techno-pragmatism: Automation now enjoys broad approval, yet enthusiasm thins among the cohorts who need proof, not promises.

Resurgent realism: Most believe the U.S. will reclaim the advanced-manufacturing mantle within ten years — but a decadal shot clock is deceptive. The clock’s ticking now. If we continue to act, invest, and build boldly today, then optimism becomes prophecy. If not, confidence could give way to cynicism.

A false dichotomy: 69% associate factories with “blue-collar” work, even as 85% say manufacturing roles demand coding, data chops, and other skills typically deemed “white-collar.” Blue-vs.-white misses the point: modern manufacturing is both. To tackle this perception gap, we need to tell better stories that resonate with people and reflect reality.

A confidence gap: Automation’s biggest cheerleaders cluster among high earners and soon-to-retire cohorts. If the real or perceived gains from technology stay gated there, today’s broad-based enthusiasm for automation could flip to opposition fast.

The full writeup is required reading for anyone personally or professionally invested in American reindustrialization.

OFF-CUFF

Our team’s take: This is a once-in-a-generation tailwind. Over eight in ten Americans want tomorrow’s turbines, chips, cars, rockets, and robots proudly stamped Made in the USA.

America rarely sees such unity, broad in its reach and clear-eyed in its demands. But unity like this is fleeting. Miss the moment, and factories of the future will fly under foreign flags.

If we can rise to the occasion — and we are certain that we can — then we secure four dividends at once: 1) durable growth, 2) greater national resilience, 3) faster cycle times, and 4) work that restores pride and purpose in communities across the country. So, let’s get to work!

— The Per Aspera team (Dan, Joy, Jeff, & Ryan)

ONE MORE THING!

You might remember that we believe the success of the Renaissance requires:

001 / more breadth (more people at the table!) and

002 / more depth (deeper understanding and execution).

Most of our work to date has focused on drilling deep, past surface-level discussions. Today’s Pulse Check is about widening the circle.

If someone you know should be part of this conversation — a founder, an engineer, a theoretical physicist, a policy wonk, a student — pay it forward. We mean that literally → forward this email! Let’s add new voices and fresh faces to the conversation.

Forwarded this from a friend? Welcome home. Join us with one click below.

Space access today is production limited: Most rockets are fully or partially expendable, requiring complex hardware to be manufactured before every flight. This drives high costs, low availability, and limited reliability. Stoke Space’s Nova is designed to end these compromises. Nova is built – from the ground up – for full and rapid reusability. After delivering payloads to orbit, both stages of the Nova two-stage rocket return to the launch site; ready to rapidly re-fit, re-fuel, and re-fly. This breakthrough is unlocked by a novel reusable upper stage, which incorporates the engine and actively cooled re-entry heat shield into a single integrated system. Liquid hydrogen, which serves as the upper stage fuel, also acts as an efficient coolant fluid, regeneratively cooling the heat shield the same way that rocket engines are cooled today (and have been for decades). This thermal protection strategy is robust, resilient, and allows for zero-refurb turnaround. The result is a paradigm shift: radically improved access to, and from, orbit – unlocking new classes of missions, making return from space as routine as reaching it, and establishing the foundation for a thriving orbital economy.

☀️ A Shenzhen of the Southwest? SoftBank boss Masayoshi Son is reportedly pitching a $1 trillion industrial megapark in Arizona. Masa’s made overtures about the advanced manufacturing project (code-named Crystal Land) to the White House, AZ officials, TSMC, Samsung, and of course, select SoftBank portfolio companies. For the unfamiliar, Masa Son thinks in centuries and invests by the billions. His hits and misses are both legendary. Even if this doesn’t materialize, the ambition is instructive (Crystal Land would be the largest industrial project in U.S. history by a wide margin). It targets a core weakness: America’s lack of co-located, end-to-end industrial ecosystems. We have no Shenzhen analog: no one-stop production zones where the sandwich is made. After decades scattering supply chains across oceans, something like this would be a meaningful step towards rebuilding a serious center of industrial gravity at home. Assuming, of course, there’s enough water.

🚢 Speaking of Shenzhen…we’re gonna need a bigger ship. The world’s largest car-carrying ship recently completed its maiden voyage, and in many ways, that ship — the BYD Shenzhen — is the perfect metaphor for this moment. It’s a monster: 9,200-car capacity, dual-fuel LNG propulsion, and battery mode for electrified port ops. The first run delivered 7,000+ EVs to Brazil, even as local opposition mounts and BYD faces flak for flooding the market with cheap EVs. See also: an ascendant BYD in Europe and Southeast Asia. As Warren Buffett saw early, BYD is no ordinary carmaker. It mines its own lithium (ironically, in Brazil). It designs and manufactures its own batteries, motors, chips, and power electronics. It owns the factory that builds the car, and now, the ship that moves it. BYD’s contract manufacturing arm alone has a ~$23B annual run rate, and it counts Apple, Huawei, Samsung, and Motorola as customers. These are the perks of near-total vertical control, from raw material to finished products. And this is a timely reminder: China outpaces the U.S. 230-to-1 in shipbuilding capacity.

🪖 The mission comes first. On the Army’s 250th birthday, four of tech’s most senior operators were sworn in as lieutenant colonels. Palantir CTO Shyam Sankar, Meta’s Andrew “Boz” Bosworth, OpenAI product head Kevin Weil, and Bob McGrew (ex-OpenAI, Palantir) will serve 120 hours a year in Detachment 201, a new Army Reserve unit designed to embed real technical leadership with DoD modernization efforts. For decades, uniformed service and tech leadership sat in parallel realities: the Pentagon promoted from within, while the Valley rarely looked outward. Detachment 201 breaks that pattern. And that’s a good thing!

🚀 Honda Type-R(&D). The maker of the Civic has pulled off something quietly historic. Last week, a subsidiary of Honda Motor Co. launched and landed a prototype rocket in Hokkaido, Japan. It was a short hop — 271 m — but a successful one, landing within 37cm of its target. This marks the first time a Japanese company has vertically launched and landed a rocket prototype. Honda’s still a long way from competing with Mitsubishi, Japan’s #1 rocket maker, but this is an intriguing R&D bet on automotive DNA: can combustion, control systems, and precision manufacturing be retooled for reusable aerospace hardware? And if the Accord is any indication…is Honda angling to build the first rocket rated for at least 300 reuses?

In Case You Missed It: last week’s antimemo covered the death of the electron and the emerging photonics arena.